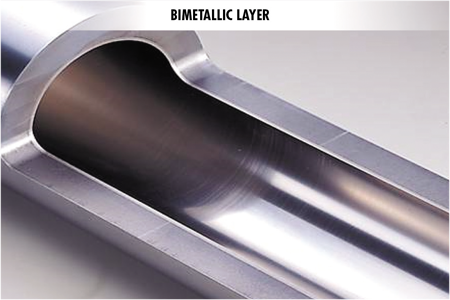

TAN STAR offers a range of bimetallic cylinders that cover various classes of glass fiber. Using our invented centrifugal casting process, the powders are efficiently distributed and free from distortions, reaching roughness parameters min 0.20 mm, max. 0.60 mm +/- 0.10 mm.

The durability life of our bimetallic cylinders varies 3 to 6 times more than other competitors’ cylinders.