With a view to meet the ever increasing market demands, present day plastic processors have resorted to the use of plastic raw materials which included all kinds of sophisticated ingredient such as glass fiber additive, carbon fiber, mineral stone powder additive, heat-resisting chemical additive, etc., thereby causing serious abrasion and to the barrel and screw as well as reducing their life span. To meet this challenge, our Co. had several kinds of screw which has shown a remarkable anti-abrasion and anti-corrosion resistance in its practical application. Not only PTA treatment on screw flights, also developed the technique of hardness coating of the entire screw surface, so as to bring more benefits to the processors.

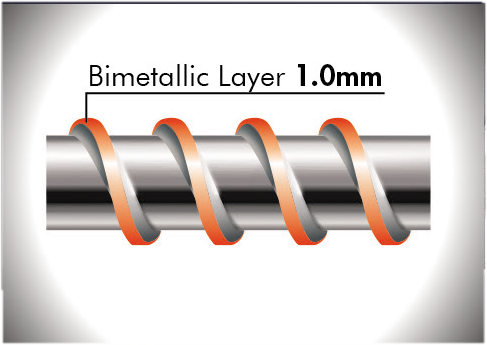

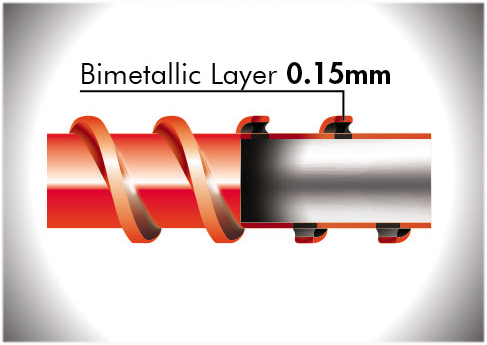

PTA-WELD

- Model: S-59 A/B

- Process: PTA-Welding

- Average Hardness: HRc 52-55

- Application Glass Fiber: Below <15%

- Recycle Material: Below <30%

- Wear Resistant: ★★★

- Corrosion Resistant: ★★★

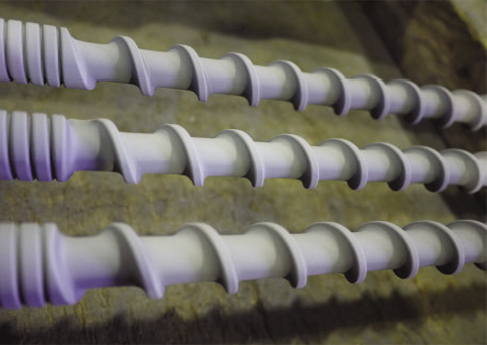

FULLY-COAT

- Model: S-42 A/B

- Process: Powder Coating

- Average Hardness: HV 1100-1400

- Application Glass Fiber: 30%-50%

- Recycle Material: Above >30%

- Wear Resistant: ★★★★★

- Corrosion Resistant: ★★★★☆

- Model: S-75 A/B

- Process: Powder Coating

- Average Hardness: HV 900-1100

- Application Glass Fiber: Above >30%

- Recycle Material: 30%-50%

- Wear Resistant: ★★★★☆

- Corrosion Resistant: ★★★★★

STAINLESS STEEL (FULLY-HARD)

- Model: S-88 A/B

- Process: Vacuum + Plasma nitriding

- Average Hardness: HRc 48-50

- Application Glass Fiber: Below <15%

- Recycle Material: Below <30%

- Wear Resistant: ★★

- Corrosion Resistant: ★★★★

TOOL STEEL (FULLY-HARD)

- Model: S-79 A/B

- Process: Vacuum + Plasma nitriding

- Average Hardness: HRc 58-60

- Application Glass Fiber: 15%-30%

- Recycle Material: 30%-50%

- Wear Resistant: ★★★★

- Corrosion Resistant: ★★★

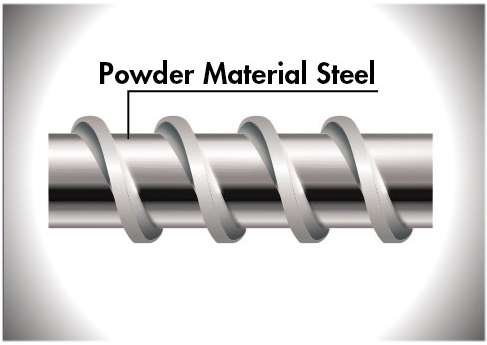

Powder Steel (Fully-Hard)

- Model: S-04 A/B

- Process: Vacuum + Plasma nitriding

- Average Hardness: HRc 58-60

- Application Glass Fiber: 15%-30%

- Recycle Material: 30%-50%

- Wear Resistant: ★★★★

- Corrosion Resistant: ★★★☆

- Model: S-23 A/B

- Process: Vacuum + Plasma nitriding

- Average Hardness: HRc >60

- Application Glass Fiber: Above >30%

- Recycle Material: Above >50%

- Wear Resistant: ★★★★☆

- Corrosion Resistant: ★★★☆